Wood chips dryer with an integrated ESP for heaters up to 10 MW

Efficient electrostatic precipitator (ESP) with an integrated fuel dryer for wet wood chips

Wood chips dryer with an integrated ESP (electrostatic precipitator)

Facts

-

- Fuel dryer combined with an electrostatic separator

- Permanent fuel savings of 6 – 15%

- Compliance with emission limits for partial and full loads

- Operation independent of the exhaust gas temperature

- Heat recovery, even at partial load operation

- Operational optimization through remote maintenance

How it works

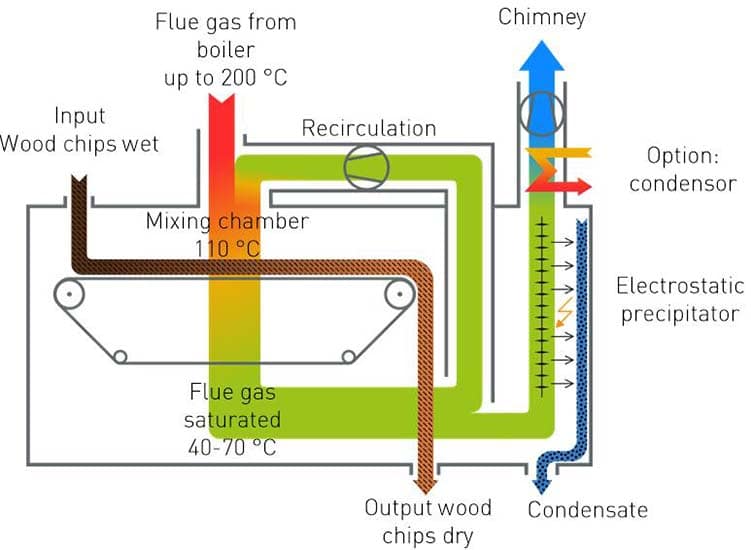

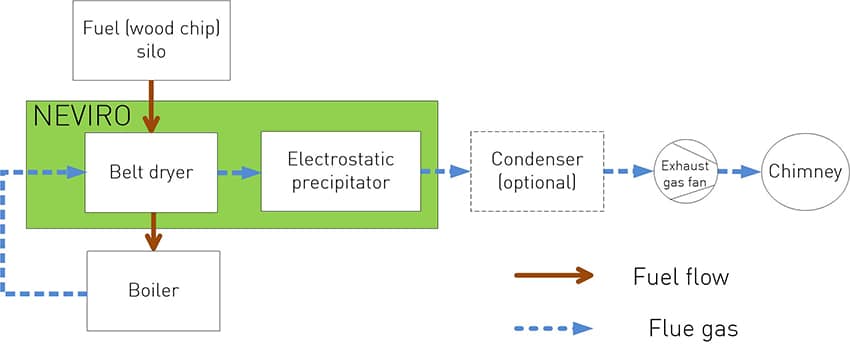

Exhaust gases from the combustion of moist wood usually leave the boiler systems at a temperature range of 140 to 200°C. The dryer exhaust system utilizes the heat energy of the exhaust gas to pre-dry the wet fuel.

The moist wood is initially fed into the system on a belt dryer. The exhaust gas of the boiler system passes through the fuel bed, absorbing the moisture from the wood chips. The saturated exhaust gas then flows through the downstream wet electrostatic precipitator.

The pre-drying of the wet wood chips is performed automatically at a feed rate equivalent to the fuel demand of the boiler.

The performance of the wood chips dryer is determined by the temperature and humidity of the exhaust gas. For instance, wood chips with a moisture content of 55% can be dried to 35% moisture with an exhaust gas temperature of 180 degrees Celsius. This leads to a substantial improvement in the combustion quality at partial and full loads.

An initial separation of coarse particles occurs during the passage of the flue gas through the wood chips. Subsequently, the saturated flue gas is cleaned by the integrated electrostatic precipitator.

Installation

Downloads

General information

Dimensional Drawings

Note: The dimensions depend on the rating and exhaust gas temperature.

![]()

Schmelziweg 2

8889 Mels-Plons

Switzerland

Tel.:+41 (0)81 511 63 00

info(at)oekosolve.ch