Electrostatic particle filter for wood and coal heating systems up to 100 kW: OekoTube Inside

The electrostatic particle filter OekoTube-Inside is approved for wood heaters up to 100 kW and is mounted in the boiler room.

OekoTube Inside – electrostatic particle filter for wood and coal heating systems

This filter is also available with a semi-automatic cleaning system. By adding simple additional measures such as longer separation distance, longer electrodes or by widening the diameter, the separation efficiency and cleaning intervals can be optimized. We recommend such as amendments for outputs over 50 kW.

Facts

- Suitable for all wood and coal fires, central heating systems fueled with wood logs, wood chips or pellets

- Gas tight so it can be installed in enclosed rooms

- Highly efficient in reducing emissions

- Massively improves the air quality

- Can be easily retro-fitted

- Very easy to clean and maintain by the chimney sweep

How it works

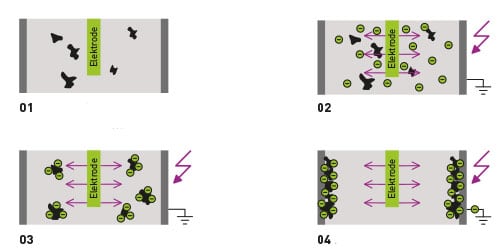

The particle filter OekoTube-Inside functions according to the electrostatic principle. The following graphics illustrate the mode of action of the fine dust filter:

The particle filter OekoTube-Inside functions according to the electrostatic principle. The following graphics illustrate the mode of action of the fine dust filter:

01 Fine dust particles flow with the exhaust air through the exhaust duct.

02 Electrons are released by a high voltage electrode.

03 The electrons move to the chimney wall by electrostatic forces. The fine dust particles become charged and move to the wall.

04 The particulate matter accumulates on the chimney wall and clumps to coarse flakes. These deposits are easily removed during cleaning by the chimney sweep.

Electrostatic particle filter offers following advantages:

- High effectiveness even with small particles

- No pull or pressure loss

- Low maintenance and operating costs

- No wearing parts

Installation

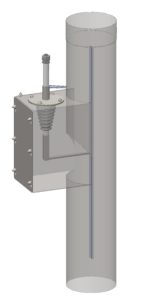

The OekoTube-Inside will be delivered with a pipe with a length of 500 or 1000 mm and can be installed by the chimney-maker in the flue pipe between boiler and fireplace inlet. The control electronics are mounted separately at the wall. A cleaning opening must be provided in front or behind the OekoTube-Inside.

A second option is the flue tube installation, which allows the the OekoTube-Inside to be fitted at an existing fireplace. A template is used to cut an opening in the existing chimney. The insulator chamber is fastened to the chimney via the opening with tension locks, – afterwards the electrode will be centered. Depending on current situation, dimensions and the chimney guide, the electrode can be shortened if necessary.

Operation and maintenance

The OekoTube-Inside automatically switches on and off via a temperature sensor. The particulate matter adhere to the inside of the stainless steel tube and become coarse particles. In this condition, particulate matter no longer poses a threat to our health.

During the fire control by the chimney sweep, the OekoTube-Inside can easily be cleaned. The separated fine dust can be removed with a conventional chimney brush. The flexible electrode evades the brush and does not need to be removed for cleaning.

![]()

Schmelziweg 2

8889 Mels-Plons

Switzerland

Tel.:+41 (0)81 511 63 00

info(at)oekosolve.ch

Contact us!

Tested particle separation

- 0-25 kW: =70 – 95%

- 25-50 kW: =65-90%

- 50-75 kW: =60-85%

- 75-100 kW: =50-80%

Technical parameters

- High-voltage 15-30 kW

- Max. power rating: 30 kW

- Standy mode: 0.7